Not for publication or display. General purpose conveyor d.

Loading of belt and impact rollers.

. BULK MATERIAL HANDLING PLANTS AND CONVEYORS. Application Design The information in this book extract is part of book and accordingly it is protected under copyright. This chains side plates have greater depth than normal thus providing a continuous carrying edge above the roller periphery.

However website visitor can copy this for his own use. Belt carrying idlers or belt troughed rollers. The receiving conveyor has a belt width of approx.

At this point of the 90s. The quantity of model TA-TPS tripper position controls required will vary for each conveyor system. They are also known as tiered or stepped conveyers and the term tripper is a colloquialism that formed after they came into widespread use.

Much like belt trippers belt plows can release material on either side of the belt at pre-designated locations. They have proved their worth everywhere because belt conveyor installations can be adapted to meet nearly all local conditions. Conveyors An Introduction to Conveyor Fundamentals RB02007 Rob Bretz 18 pages.

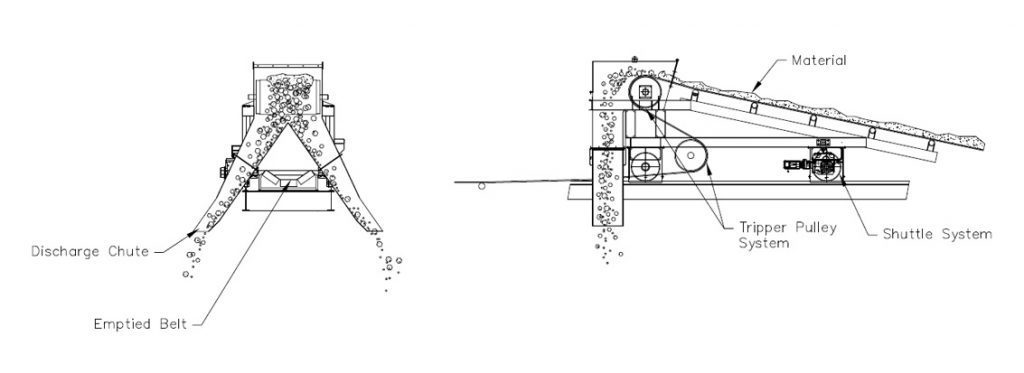

The demand for ever increasing capacities and ever longer conveying lengths. The tripper car moves in both directions to make a long pile on one or both sides of the belt conveyor. T e is the final summarization of the.

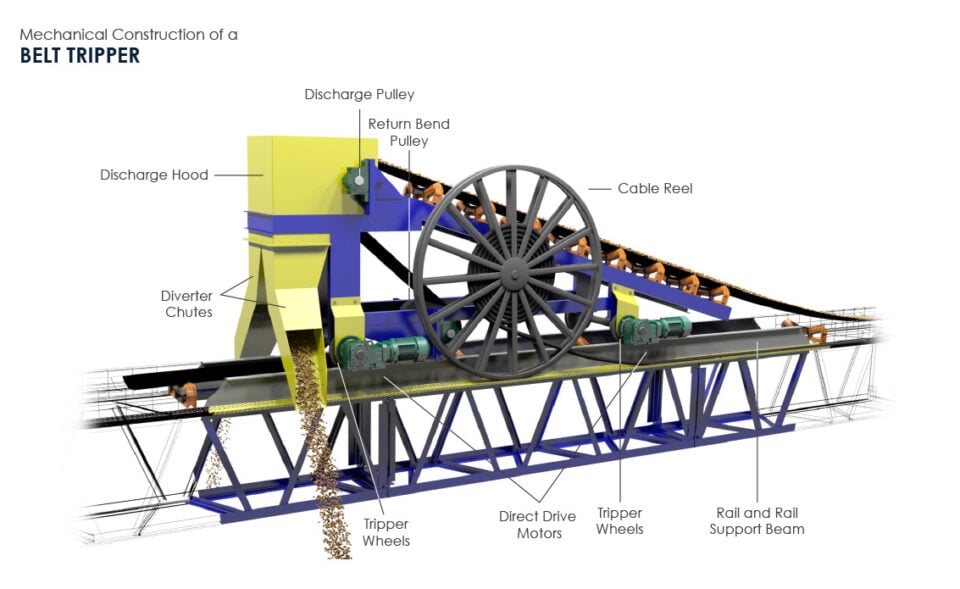

Bulk materials discharge off the Belt Tripper to another belt conveyor to storage or to processing. The microswitches can be wired to trigger a warning signal or be connected directly to the motor starter circuit to stop a conveyor. Ous conveyor belt misalignment and con stant spillage in the load zone.

FEECO belt plows are designed to increase a belt conveyors material discharge control capabilities. Special purpose conveyor. A tripper conveyor is a form of conveyor belt used in construction mining and other large-scale earth-moving businesses.

SKE provide traveling tripper conveyor design service. The discharge plough is a board placed at a certain angle α to the longitudinal axis of the. - A throw off carriage known as tripper only used for bulk materials NB.

INTERNATIONAL STANDARDS Conveyor chain like transmission chain can be manufactured to a number of different international standards. Conveyor Name Tripper 1 Filename Tripper Conveyor Location Date February 16 2016 Description Tripper Conveyor Example Sidewinder v606 - Conveyor Design Software Advanced Conveyor Technologies Inc. Troughed belt conveyor capacities.

The bypass conveyor is an approx. The purpose of the belt tripper or traveling tripper is to add versatility and functional-. Of the conveyor system.

While there are many types of conveyor systems in use throughout the world this rudimentary knowledge of the fundamentals gives you an advantage when specifying or changing your current systems. According to the design a. The loaded conveyor at the design velocity of the belt V in fpm.

Depending on the height of the pillars tripper conveyors are capable of large quantity stockpiles. The tripper conveyor consists of a horizontal Belt Conveyor supported over the. Vertical adaptability Occasionally material needs to be delivered at a certain angle and the conventional conveyors can handle materials only to angles around 16-18 degrees.

24052004 Dunlop Conveyor Belt Design Manual Page 30 of 33 Belt width W 1200 mm Conveyor length L 500 m Lift H 45 m Max capacity τ 4500 thr Belt speed S 35 ms Skirt length Ls 3 m Material conveyed Iron Ore Idler Data. 1 To determine the effective tension T e it is necessary to identify and evaluate each of the individual forces acting on the conveyor belt and contributing to the tension required to drive the belt at the driving pulley. Page 4 33 Conveyor Profile Overall length 2116 ft -Overall height 178 ft - True Length 21682 ft.

Cema belt tension theory. The FEECO design incorporates a raising bed plate that allows the use of a plow even on troughed belts. Full PDF Package Download Full PDF Package.

Hollow and solid pin chain has an optional side plate design known as deep link. Standard belt conveyor pulleys. The types of conveyors conveyor components and relevant terminology.

Capacities up to 20000 cubic feet per hour can easily be. BELT TRIPPERS FEECO belt trippers are custom designed and built to accommodate your desired specifications with the same guidelines you can expect from all of our equipment ie precision engineering quality components and heavy-duty construction. The overall usable length of the conveyor will be approximately 75 of the actual length of the stacked conveyor frames.

Page 1 Preface 5 2 Symbols and Units 6 3 General design fundamentals for belt conveyor systems 8 31 Motional resistances and power required in the steady operating state 8 311 Power required 8 312 Motional resistances 9 32 Motional resistances and driving forces in non-steady operating states 12 321 Start Up 12 322 Stopping 13 33 Belt tensions 14 331. 11 metre 42 inch wide conveyor belt which runs at 36 metres per second 700 feet per minute and which has a capacity of 1400 tonnes per hour. Travelling tripper on conveyor Nos.

According to the purpose c. Belt conveyors - basic calculations. A Tripper Conveyor is a form of conveyor belt used in construction mining and other large-scale earth-moving businesses.

This particular type of conveyor was designed to ferry debris earth rocks etc uphill. Portable mobile conveyors ii. Belt Trippers are short belt conveyors that can be positioned at different points along a main belt conveyor to trip or divert the flow of bulk materials off through a chute.

This particular type of conveyor was designed to ferry debris earth rocks etc. Either a single unit or a pair of units can be used depending on the arrangement of the shuttle conveyor. They are work-safe and economical.

An additional must for a tripper driven concept conveyor is gentle predictable preferably linear conveyor acceleration giving the need to squarely address conveyor starting devices prior to going down the tripper driving road. Tripper driving is becoming a very accepted alternative to two or three. Conveyor belts have been used for decades to transport bulk and unit loads.

Other accessories include movable trippers and belt plows. Some common applications include stockpiling for winter discharging to bins or ships and linear stockpiling inside storage buildings.

Belt Trippers Belt Conveyors Robotic Palletizers Bagging Scales Chantland Mhs

Design Aspects Of Multiple Driven Belt Conveyors Semantic Scholar

Traveling Tripper Conveyor Design For Bulk Materials Ske

0 comments

Post a Comment